The Lancan Technology

Reinventing how the world forms rigid packaging.

At Lancan, we are not simply updating packaging—we are transforming it. Born from the need to replace outdated, waste-heavy formats, the Lancan technology platform introduces a new standard in performance, sustainability, and efficiency. Engineered to integrate directly into your existing packaging line, our patented solution turns a single flat blank into a high-integrity, rigid paper container — seamlessly, sustainably, and at scale.

Whether you are replacing composite cans, plastic bottles, Bag-in-Box Systems, Tetra Paks, or cosmetic jars, paper cups, Lancan delivers a universal forming system with one purpose: to future-proof your packaging operations while eliminating non-recyclable paper and plastic waste.

What makes Lancan different?

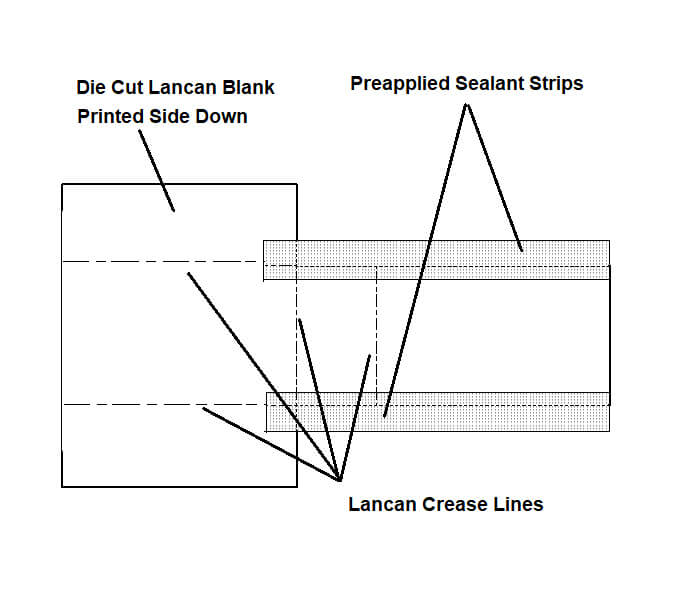

Lancan’s design is deceptively simple but profoundly powerful. It begins as a flat-printed paperboard blank. Through a patented forming and ultrasonic or induction sealing processes, that blank becomes a leak-resistant, shelf-stable, high-barrier container — compatible with everything from dry goods to liquids and semi-liquids.

Our containers are designed to match or exceed the durability of traditional rigid formats — without the multi-material complexity or end-of-life limitations. No aluminum liners. No petroleum-based adhesives. Just intelligent material science, thoughtful engineering, and packaging that performs across industries.

The Core Structure

Built for Sustainability and Strength

Lancan containers are constructed using layered paperboard and barrier coatings tailored for the intended contents — moisture, vapor, and grease resistance options available. The structure includes:

- Sustainably sourced fiberboard as the base substrate.

- Bio-based or recyclable barrier layers, engineered to protect product quality.

- Heat-sealable finishes, compatible with most top-sealing systems.

Unlike Tetra Paks or composite cans, Lancan does not rely on aluminum or unrecyclable polymer laminates. The result? An 80%+ paper structure that is both high-performing and easy to recycle — or compost, where infrastructure allows.

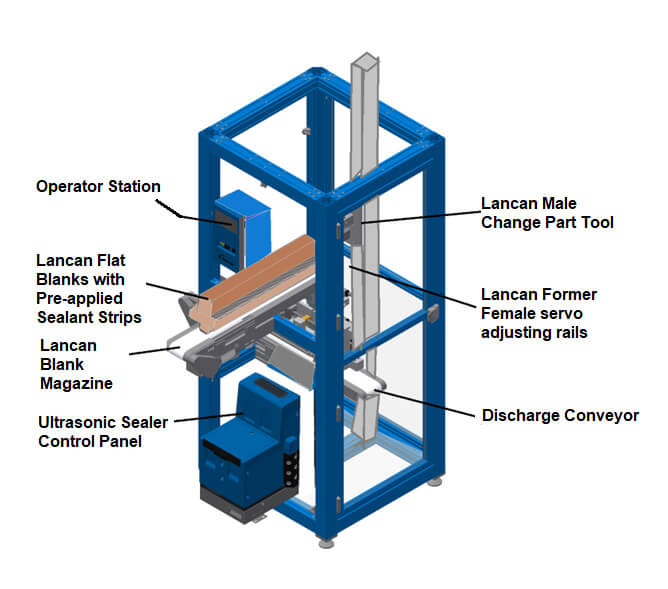

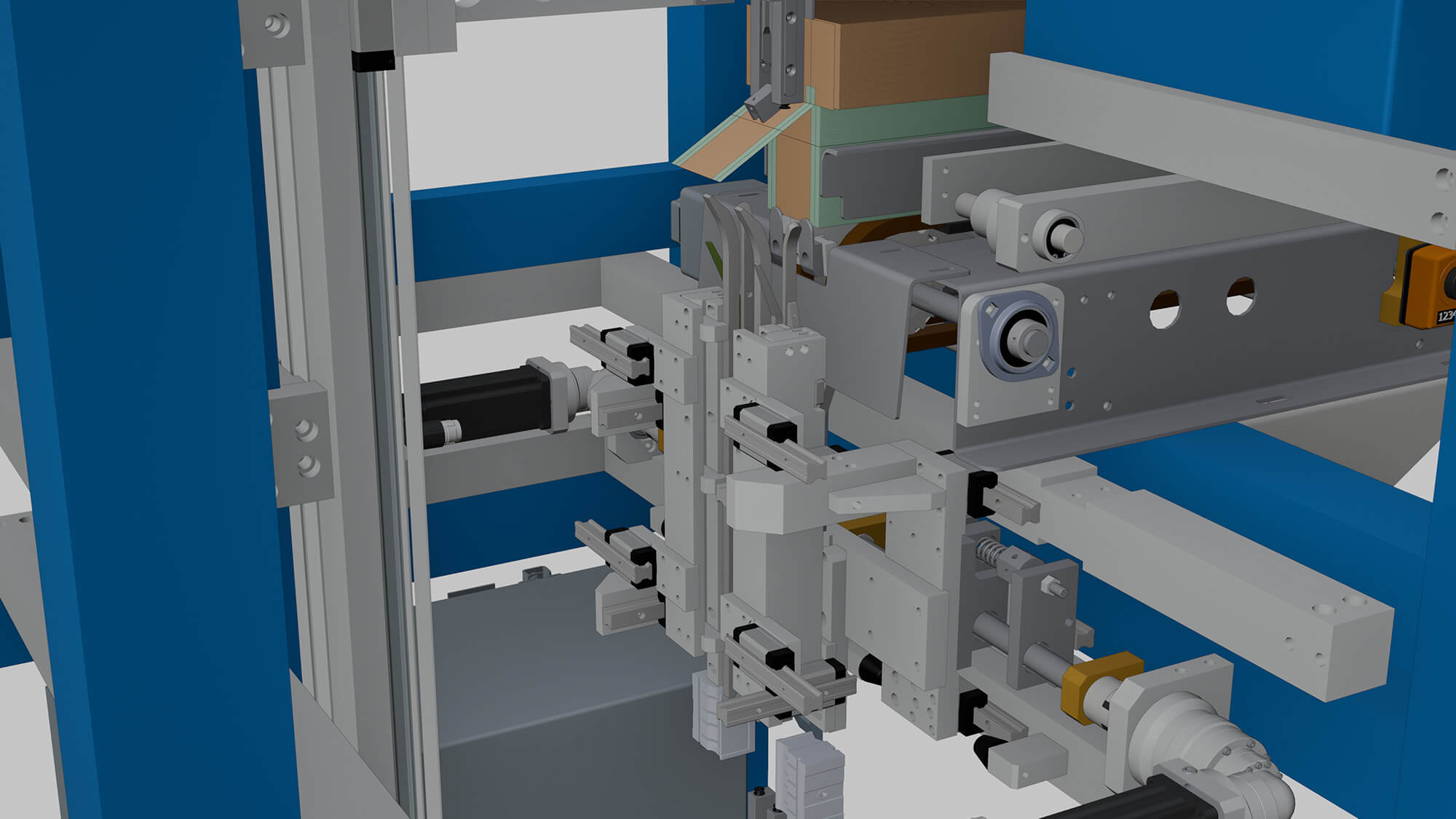

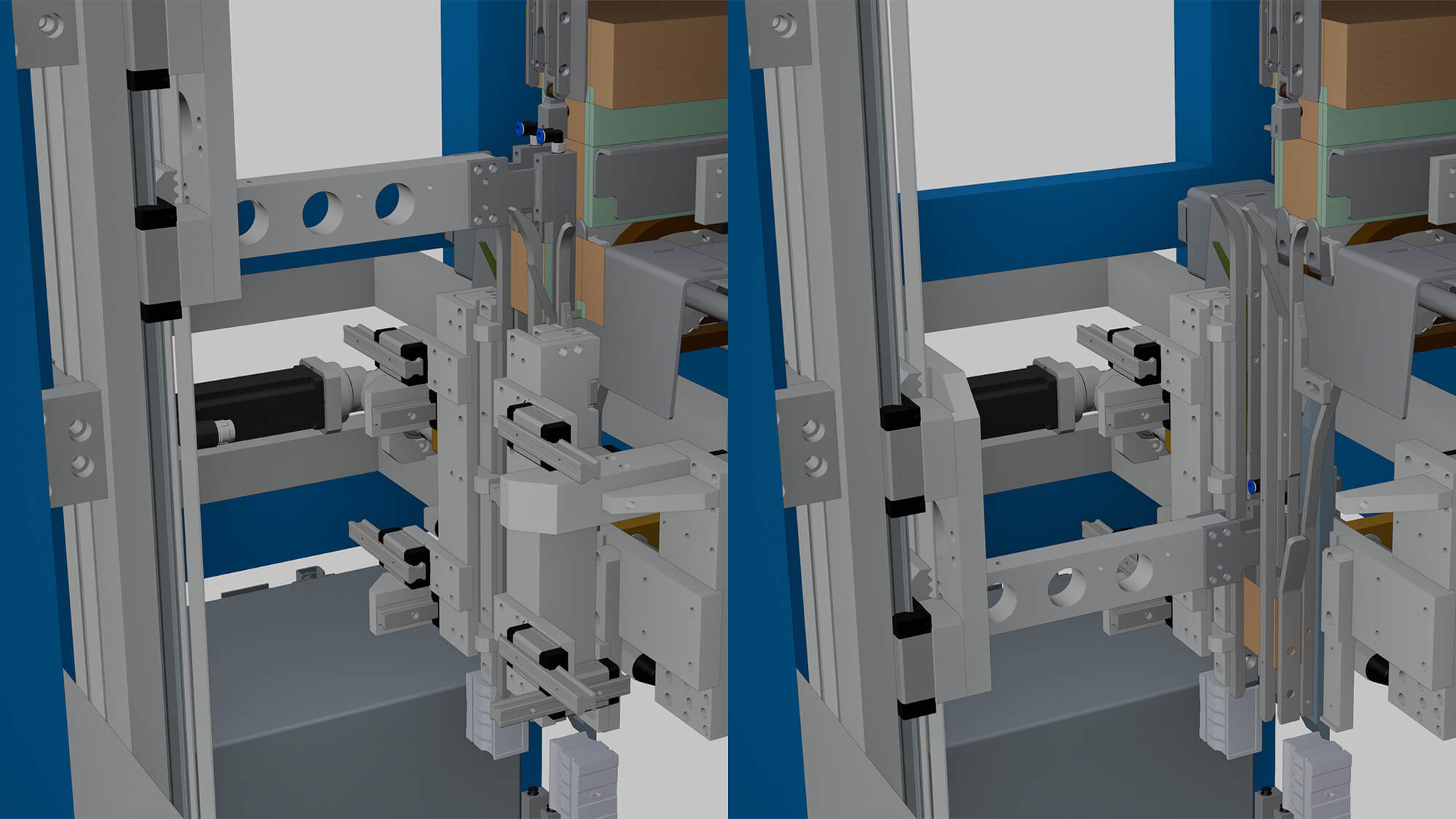

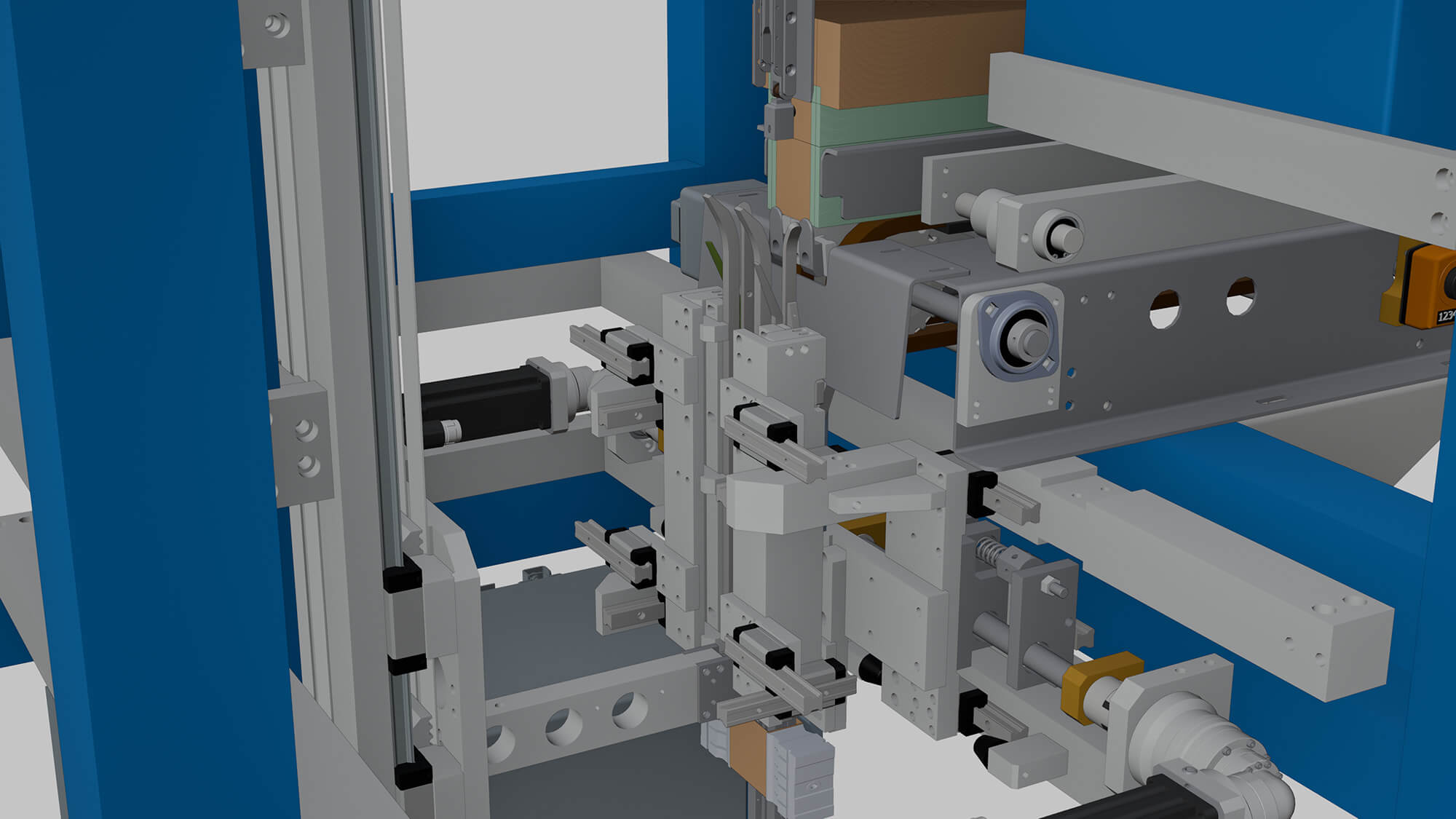

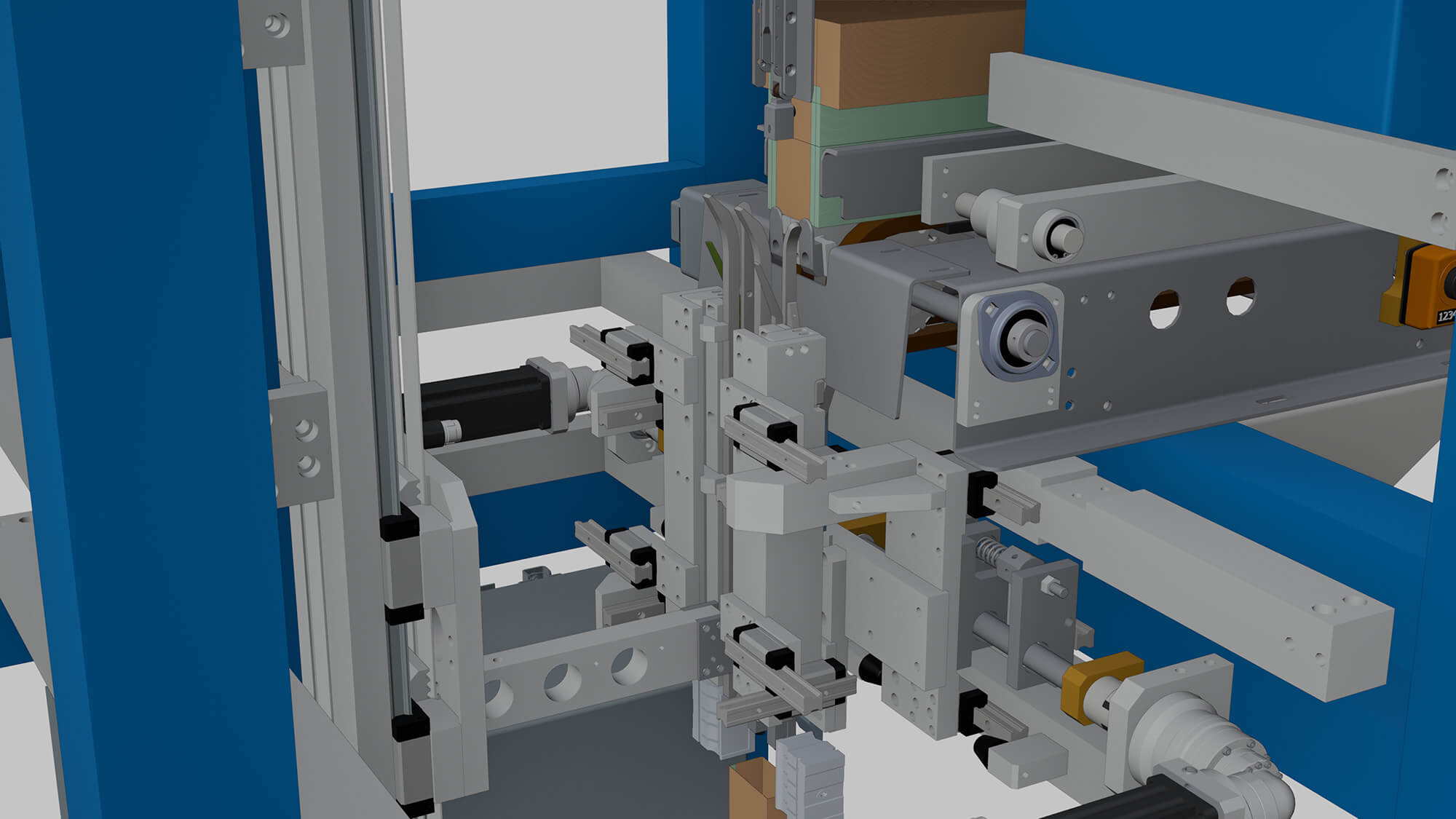

The Lancan Transformer™

The Lancan Transformer is the technological heart of our solution — a universal Lancan forming platform designed to bring flat blanks to life in seconds. Developed in partnership with AFA Systems, this servo-controlled unit forms, seals, and discharges each Lancan with precision and speed.

Key Capabilities

Every Lancan Transformer is optimized for your operational needs — whether you require small-batch agility or high-volume output.

How It Works

Precision Engineering

In a fully automated sequence, the Lancan Transformer forms and seals each unit with exacting control.

The following video demonstrates the Lancan Transformer’s simplicity of design and operation.

With six models available, including both single- and multi-head formers, the Lancan Transformer accommodates a broad size range—from compact single-serve formats to full-scale bulk containers.

Models at a Glance

Whether you are a converter, brand owner, or OEM partner, Lancan offers the scalability to suit both small-scale pilots and global rollouts.

| Model | Type | Output Capacity | Size Range |

|---|---|---|---|

| LT-SCF | Small Range Single Head |

Up to 50/min | 2.0” x 1.0” x 2.0” to 6.0” x 4.0” x 11.0” |

| LT-SMH | Small Range Two Head |

Up to 150/min | 2.0” x 1.0” x 2.0” to 6.0” x 4.0” x 11.0” |

| LT-SMT | Small Range Four Head |

Up to 200/min |

2.0” x 1.0” x 2.0” to 6.0” x 4.0” x 11.0” |

| LT-LCF | Large Range Single Head |

Up to 30/min |

4.0” x 4.0” x 3.0” to 10.0” x 6.0” x 14.0” |

| LT-LMH | Large Range Two Head |

Up to 60/min | 4.0” x 4.0” x 3.0” to 10.0” x 6.0” x 14.0” |

Compatibility & Integration

One of Lancan’s most valuable attributes is its compatibility with existing packaging infrastructure. Our containers can run on the same top-sealing systems currently used for composite cans or plastic bottles, with only minor modifications. This dramatically reduces changeover costs and shortens deployment timelines.

No need to overhaul your operations — just replace the Container Depalletizer or Bottle Unscrambler with the Lancan Transformer and start forming sustainable containers on demand.

The future is flat.

The future is fiber.

Lancan is not just an alternative to plastic — it is a better way forward. Through a clever convergence of sustainable materials, smart automation, and seamless integration, we are redefining how packaging gets made, filled, and delivered.

Join the shift toward a lighter, cleaner, and more efficient packaging system — one flat-formed blank at a time.